|

| May 19, 2020 | Volume 16 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Plastic camshaft module for cars developed and tested

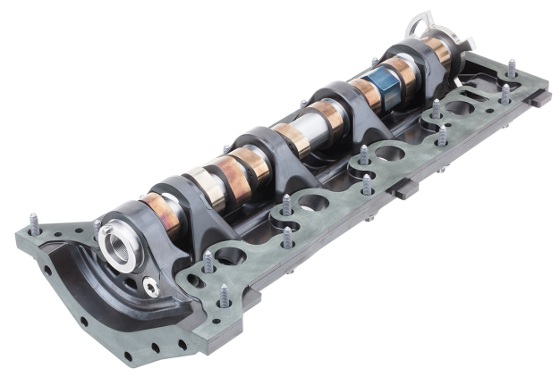

A new plastic camshaft module features a monolithic design with integrated bearings. [Image: © Fraunhofer ICT]

Plastic in cars reduces their weight. Currently, however, camshaft modules, which are a key component of powertrains, are still being made from aluminum. Now, a research team from the Fraunhofer Institute for Chemical Technology ICT, in collaboration with its partners, has succeeded in manufacturing a camshaft module from fiber-reinforced thermoset polymers. This lightweight design element helps lower engine weight and reduces assembly costs, according to the developers.

Camshafts ensure that the charge-cycle valves in internal combustion engines are opened and closed reliably and precisely. These valves are located in the camshaft module, the standard material for which is still aluminum metal.

But automotive manufacturers and suppliers are putting great effort into producing powertrains and their components in lightweight design. Weight reduction is one of the most effective methods for using less energy and reducing CO2 emissions.

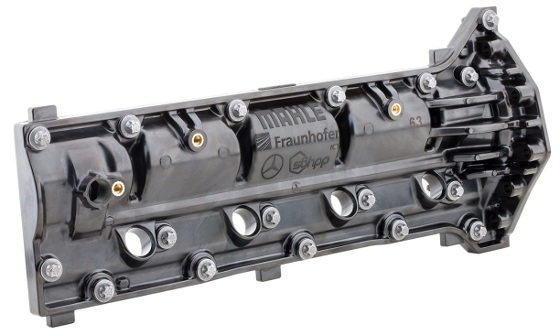

Researchers at Fraunhofer ICT in Pfinztal, Germany, are supporting the automotive industry in its efforts with a newly developed camshaft module made of thermosetting composite materials. This lightweight camshaft module was developed in cooperation with the MAHLE Group and associated partners Daimler AG, SBHPP/Vyncolit NV, and Georges Pernoud. The German Federal Ministry for Economic Affairs and Energy (BMWi) has been funding the project.

When it came to the choice of the right material, the project partners opted for high-strength, fiber-reinforced thermoset polymers, because they are able to withstand high temperatures and mechanical and chemical stresses such as those caused by synthetic motor oils and coolants.

"We contribute the know-how regarding how to design the component geometries to suit the material and the process so that they satisfy all requirements," said Thomas Sorg, a researcher at Fraunhofer ICT. "The camshaft module is located in the cylinder head, so normally in the upper installation space of the powertrain. Here, it makes particular sense to reduce weight, since doing so also contributes to lowering the vehicle's center of gravity."

Castings made from aluminum require extensive reworking after they've been cast, resulting in high costs. Using fiber-reinforced thermoset polymers allows near-net-shape manufacturing, which requires comparatively little reworking and leads to reduced production cost. Also, at up to 500,000 units, the service life of thermoset polymer injection molds is significantly higher than that of aluminum high-pressure die cast molds. Furthermore, plastics reinforced with a high fiber content have a much lower CO2 footprint compared with aluminum, since the metal is very energy intensive to manufacture.

The developers say this fiber-reinforced thermoset polymer component lowers engine weight. [Image: © Fraunhofer ICT]

And there is another advantage. Noise, vibration, and harshness (NVH) characteristics are high up on the list of factors used to assess vehicle quality. Polymers have good damping characteristics. "This makes it very easy to optimize the acoustic performance of the camshaft module," said Sorg.

The camshaft module features a monolithic design with integrated bearings -- in other words, it is manufactured in one piece, thus reducing assembly time in the engine manufacturing plant. Car manufacturers receive a pre-assembled module from their supplier and can mount it on the engine with just a few simple mounting operations. This eliminates the need for separate, time-consuming installation of the camshaft. This innovative solution boasts an additional advantage: aluminum inserts in highly stressed areas of the new camshaft bearings absorb the direct forces.

During initial tests on the engine test stand, the researchers observed positive operating performance, and weight savings were demonstrated compared with the aluminum reference part. According to the engineers, the camshaft modules made of thermoset polymer material can be produced much more easily than their counterparts made of light metal; it can be done economically in an injection molding process.

Simulation calculations help engineers design and validate the prototype before the manufacturing process begins. Although the stiffness of the thermoset polymer is only a quarter of that of aluminum, design measures enabled the team to adhere to the maximum allowable deformation.

After 600 hours of testing on the engine test stand, the researchers claim the lightweight design element demonstrated flawless functionality in a state-of-the-art internal combustion engine. With the aid of the planned fuel injection tests, the project partners want to prove the functionality and the NVH characteristics taking the gas forces of the combustion process into account.

Source: Fraunhofer ICT

Published May 2020

Rate this article

View our terms of use and privacy policy